Looking for an embedded systems development partner?

Learn the key technical and business factors to choose the right embedded design company.

Choosing the right embedded systems development partner can determine whether your electronics product succeeds in the market or fails during development. Startups, manufacturers, and product teams often underestimate how critical hardware architecture, firmware quality, PCB design, and testing processes are when outsourcing embedded system design. Selecting an experienced embedded systems development partner ensures technical reliability, faster time to market, and reduced product risk.

This guide explains the key technical and business factors to evaluate before choosing an embedded development company.

What Does an Embedded Systems Development Partner Do?

An embedded systems development partner provides end-to-end support in building electronic products that rely on microcontrollers, processors, and integrated hardware-software systems.

Typical services include:

- Custom embedded hardware design

- Firmware development

- PCB design and layout

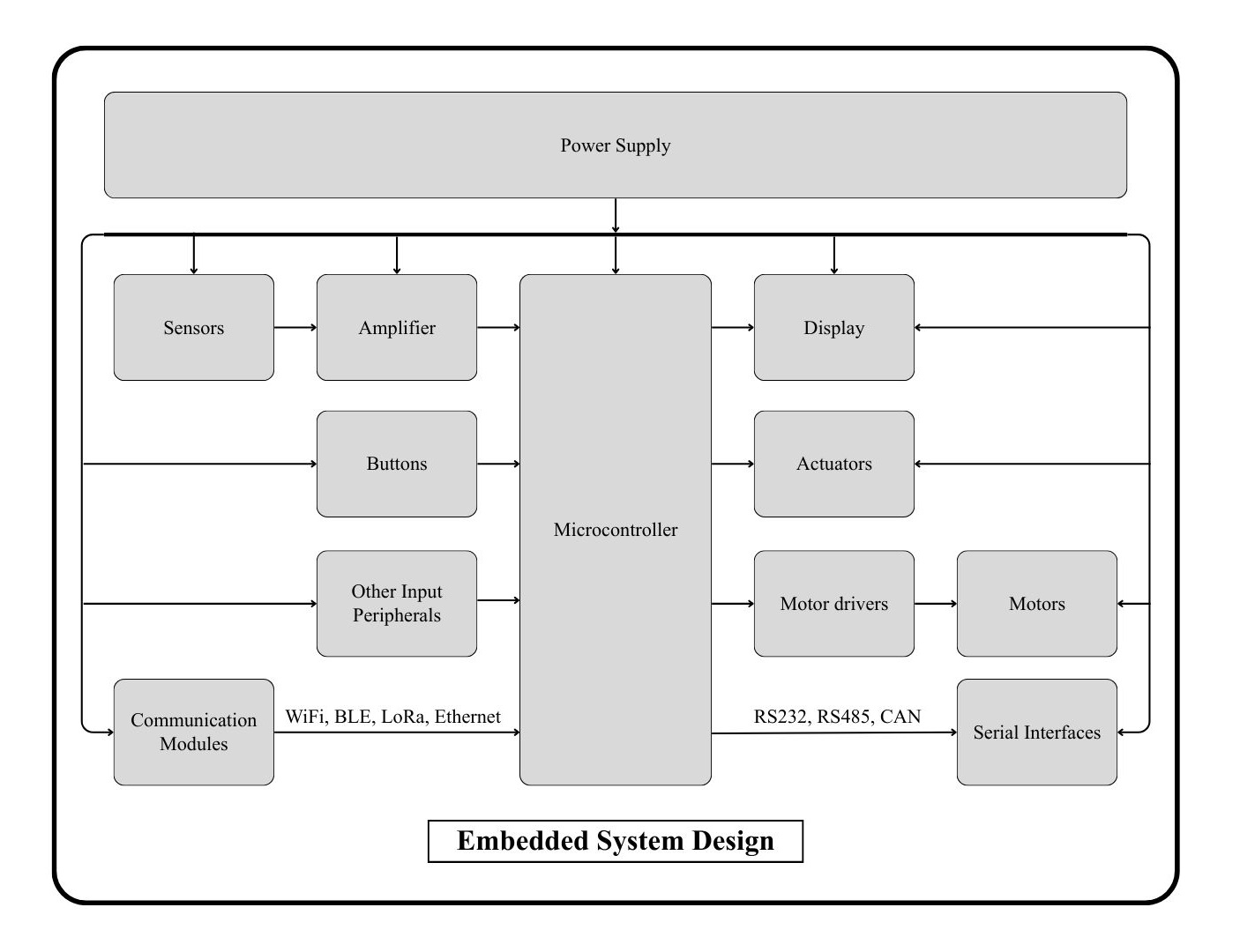

- Sensor and communication integration

- System integration and validation

A capable partner does more than coding — they handle the complete electronics design lifecycle.

Key Factors to Evaluate Before Choosing a Partner

1. Technical Expertise in Embedded Hardware

Check if the company has experience designing microcontroller-based systems, power management circuits, communication interfaces, and sensor integration. Poor hardware design leads to long-term product failures.

2. Firmware Development Capability

Firmware controls device behavior. Evaluate their experience in:

- Real-time systems

- Peripheral driver development

- Communication protocols (UART, SPI, I2C, CAN, Ethernet)

- Memory optimization

Weak firmware results in instability and field issues.

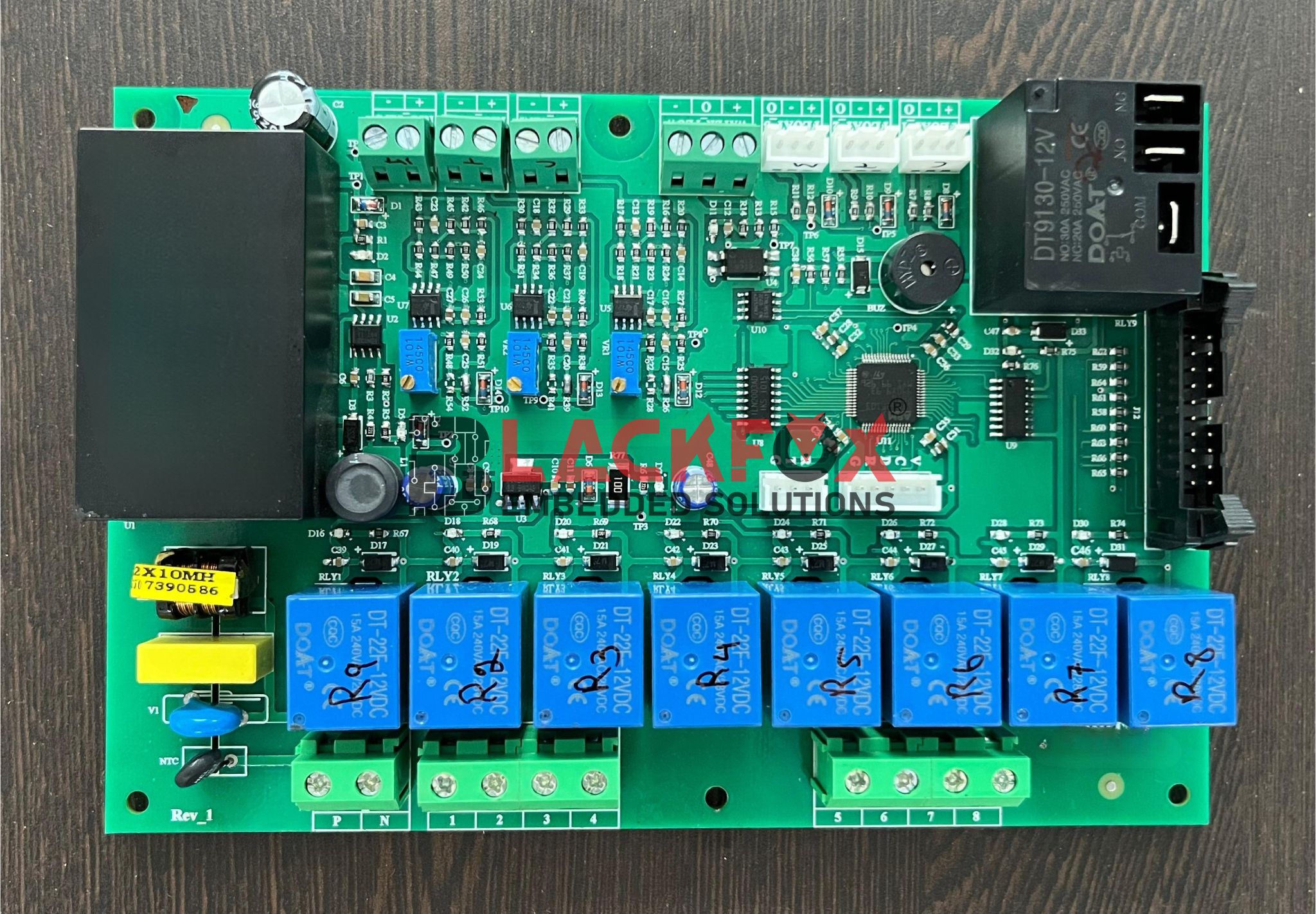

3. PCB Design & Prototyping Experience

A strong embedded partner should provide:

- Multi-layer PCB design

- Signal integrity consideration

- Thermal management

- Prototype development and debugging

PCB errors are among the top reasons for product delays.

4. Industry Experience

Embedded solutions vary across industries such as manufacturing, automotive, agriculture, and IoT. Industry exposure means they understand environmental, reliability, and compliance requirements.

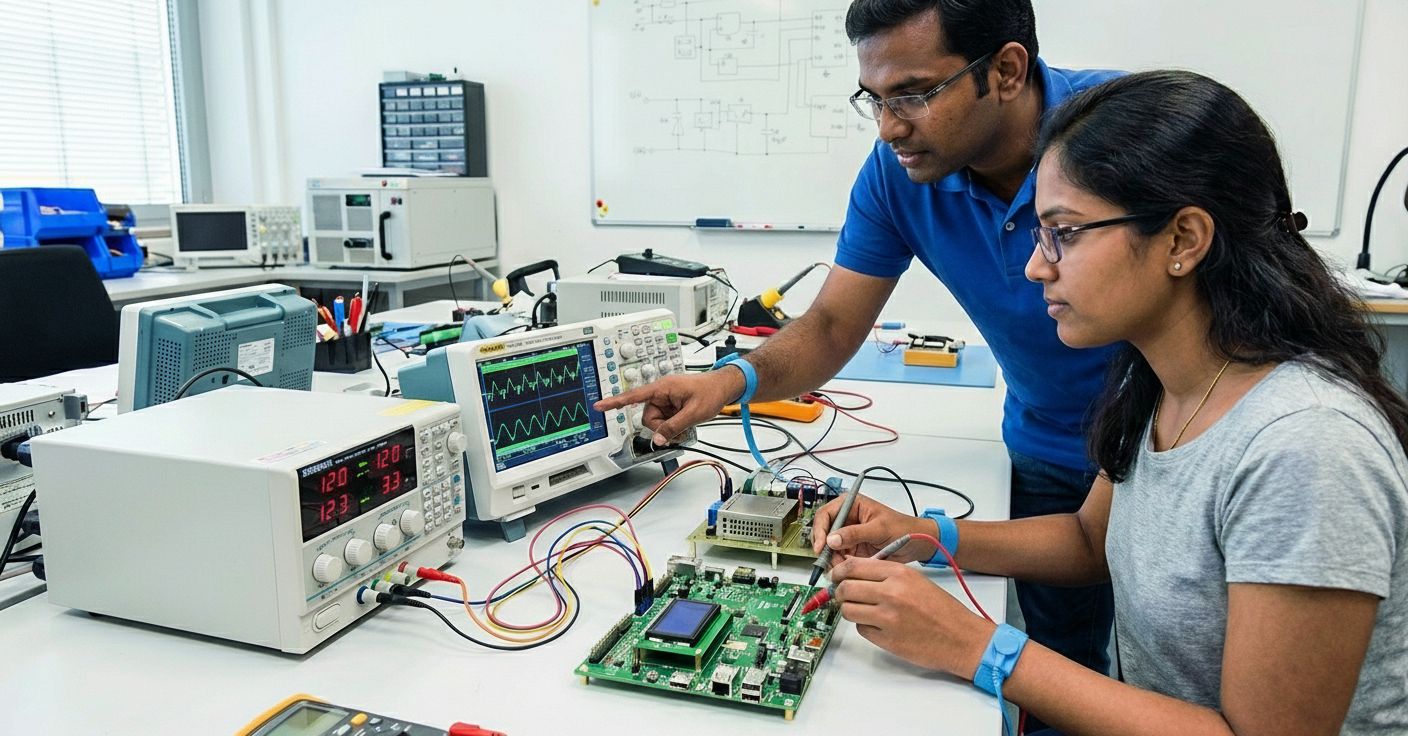

5. Testing & Validation Process

Professional embedded development includes:

- Hardware validation

- Firmware testing

- Stress and environmental testing

- Field testing support

Without proper testing, products fail after deployment.

Technical Questions You Should Ask

Before signing an agreement, ask:

- Which microcontrollers and processors do you commonly work with?

- Do you provide end-to-end product development?

- How do you handle hardware debugging and board bring-up?

- What validation and testing procedures are followed?

- Do you support transition from prototype to production?

The answers reveal their technical maturity.

Risks of Choosing the Wrong Embedded Partner

Selecting a partner without proper evaluation can lead to:

- PCB design issues causing hardware re-spins

- Firmware instability and crashes

- Communication failures in the field

- Delayed product launch

- Increased development costs

The cheapest option often becomes the most expensive mistake.

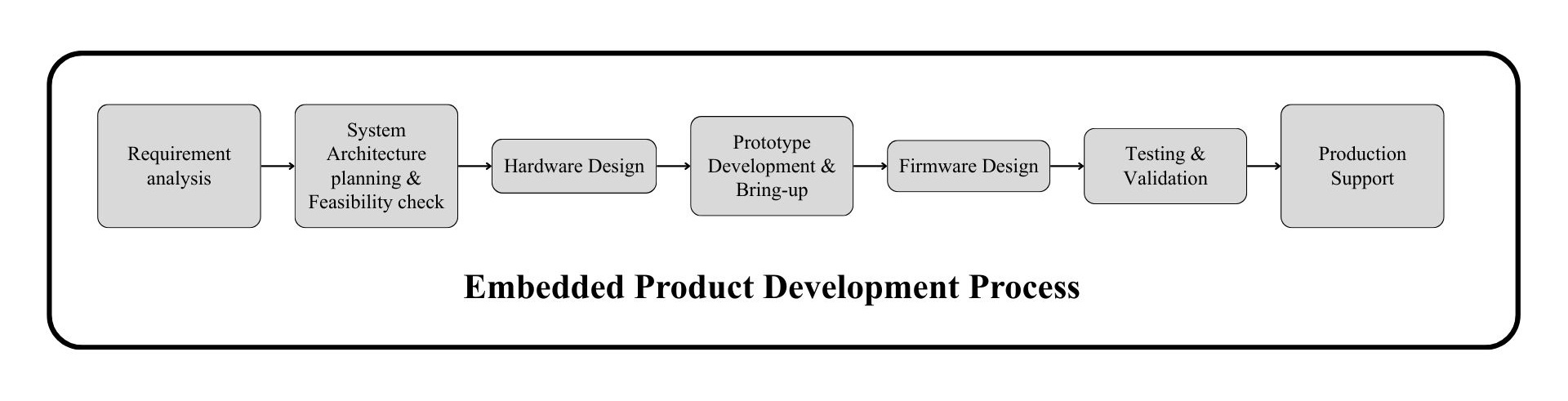

How Professional Embedded Companies Handle Development

Experienced embedded systems companies follow a structured process:

- Requirement analysis

- System Architecture planning & Feasibility check

- Hardware Design

- Prototype Development & Bring-up

- Firmware design

- Testing & Validation

- Production Support

This systematic approach ensures reliability and scalability.

Conclusion

Choosing the right embedded systems development partner is a strategic decision, not just a vendor selection. Technical depth, testing processes, industry experience, and end-to-end capability matter more than low pricing. A strong development partner reduces risk, improves product quality, and accelerates market entry.

Looking for an Embedded Systems Development Partner?

Blackfox Embedded Solutions provides embedded hardware design, firmware development, PCB design, and end-to-end product engineering services for startups and industrial businesses. Contact our team to discuss your project requirements.

Frequently Asked Questions

What does an embedded systems development company do?

An embedded systems development company designs hardware, develops firmware, creates PCB layouts, integrates sensors and communication modules, and supports testing and validation for electronic products.

Do you provide both hardware and firmware development?

Yes, professional embedded product development includes hardware design, PCB development, and firmware programming to ensure reliable system performance.

Do you support prototype-to-production development?

Yes, embedded development services typically cover prototype design, PCB optimization, testing, and transition to production-ready hardware.

Do you work with companies in Coimbatore and Chennai?

Yes, we support startups, manufacturers, and industrial businesses in Coimbatore and Chennai with embedded systems, PCB design, and electronics product development.

Do you provide services across India?

Yes, embedded systems and electronics product development projects are handled for clients across India through remote collaboration and structured engineering workflows.

Can you handle international embedded systems projects?

Yes, embedded hardware design, firmware development, and PCB engineering services are provided for global customers using standardized documentation and validation processes.

Which industries use embedded systems and electronics product development?

Embedded solutions are widely used in industrial automation, manufacturing, IoT devices, agriculture technology, automotive electronics, and smart systems.

Comments are closed